ADDRESS30-092 Kraków, ul. L.Kmietowicza 11

PRODUCTION PLANTJANUSZOWICE 32-090 SŁOMNIKI

low price, production of dimension

high precision

durability

low curb weight

possibility high loads

aesthetics - flat in both directions

wide range of applications

ease of installation

work platforms, platforms in factories, fences, kerb angle frames, footbridges, gangways for disabled people, manhole cover, fill shelves, ceilings and many others

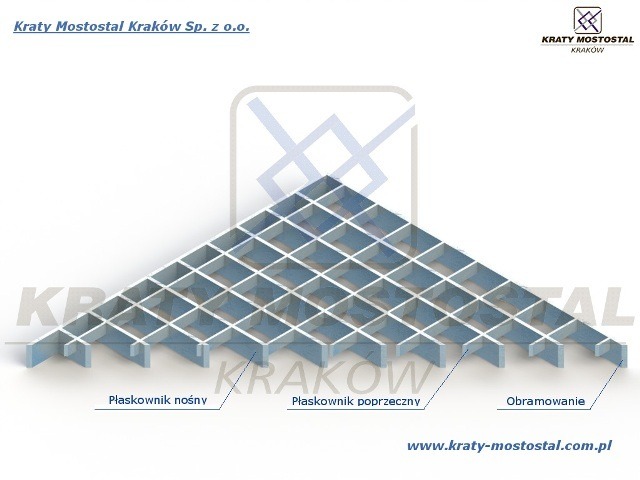

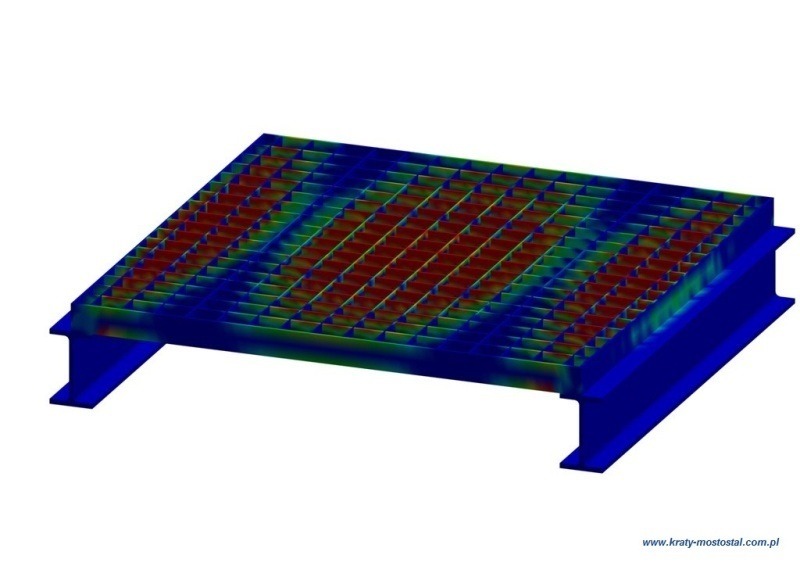

Structural components of KWO product are load bearing bars and cross bars. The connecting procedure involves pressing a cross bar under great pressure (up to 2,000 kN) into a specially notched flat bearing bar. This process creates a permanent press locked connection that keeps a specific spacing between the bars (the mesh).

Load bearing bars are designed to wear loads on platform gratings during their use, while cross bars give the lattice their grid form, and join and position bearing bars with respect to one another.

The length of a load bearing bar should coincide with the span between the beams of the supporting structure, provided that the backrest width on a supporting beam is equal to the grating height, and not lower than 30 mm. The load bearing dimension is traditionally marked as "L" and called the grating length. The second dimension is width "B" which is the length of a cross bar.

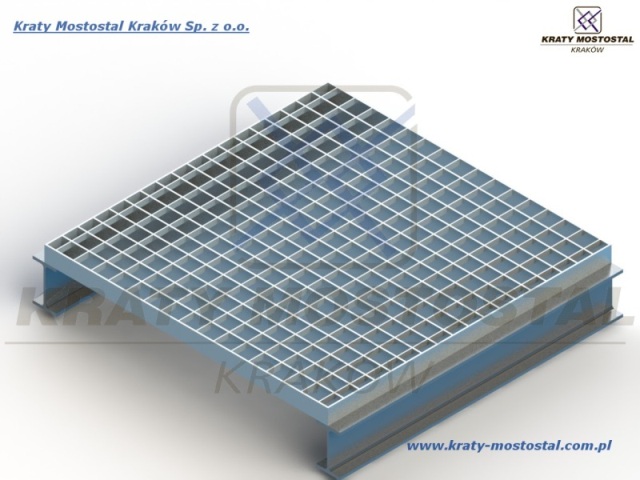

Our standard pressed gratings are framed with a flat edging bar with the same thickness and height as the load bearing bar, but to meet our customers' needs, we also make frames of other profiles (angle and U-bars, and hollow profiles, etc.); and the gratings can be also manufactured with no edging.

Distance between load bearing and cross bar is the mesh size of a grating. The mesh size of our pressed gratings ranges usually from 11.1 mm to 99.9 mm (11.1 mm panel).

Our pressed platform grating is made in accordance with DIN 24537 standard, tolerances indicated in RAL-GZ 638 instructions and technical specifications for their manufacturing. Overall dimensions of panels are made with negative tolerances from 0 to -4 mm (note: at the design stage, the spacing between gratings should be assumed to be 0).

Our products are manufactured of S235JR grade steel as per EN 1002. At the final stage of production, our gratings are hot-dip galvanised in compliance with ISO EN 1461.

We encourage our clients to request our recommendations to ensure proper selection of platform gratings.

| Height [mm] | 20; 25; 30; 40 | 20; 25; 30; 35; 40; 50 | 30; 40 |

| Thickness [mm] | 1.5 | 2; 3 | 4 |

| Height [mm] | 9 | 9 | 9 |

| Thickness [mm] | 1.5 | 2 | 2; 3 |

| Mesh size (space between bearing bars) | 16; 22; 33; 44; 55; 66; 77; 88; 99 i inne | ||

| Mesh size (space between cross bars) | 22; 33; 44; 66 | 11; 22; 33; 44; 55; 66; 99 | 33; 44 |