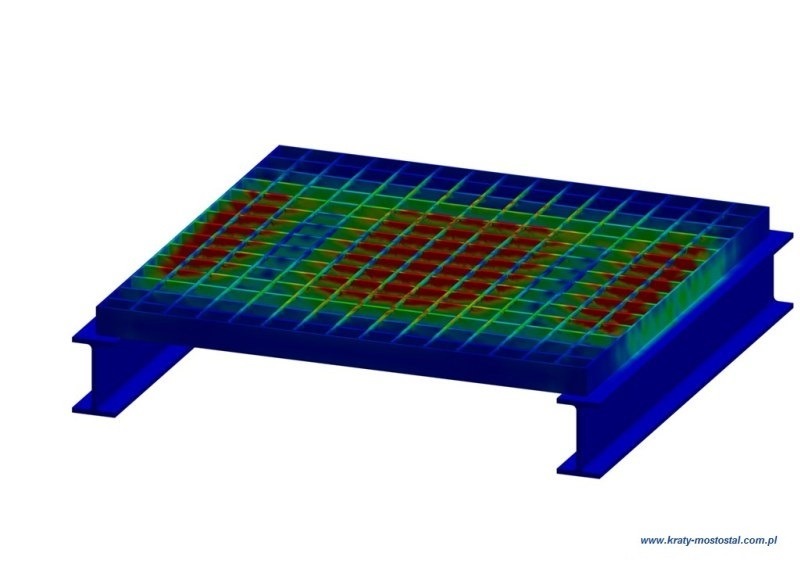

The essential operation in the manufacturing of welded grating is connecting flat bars with rods. The joining method used is resistance welding which involves forcing a 2500 kVA current through the point of contact while applying downforce of 1000 kN. This technology is used to manufacture welded grating mats with dimensions of 6100 x 1000 mm which are then cut to desired sizes.

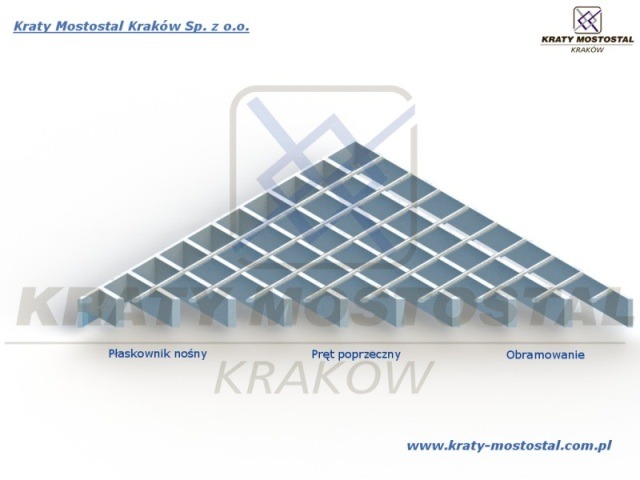

Structural components of welded grating are load bearing bars and cross twisted rods with a diameter of 5 or 6 mm (depending on the thickness of a load bearing bar). Bearing bars are designed to carry loads applied to the grating while cross rods provide suitable placement of and stability to the load bearing bars.

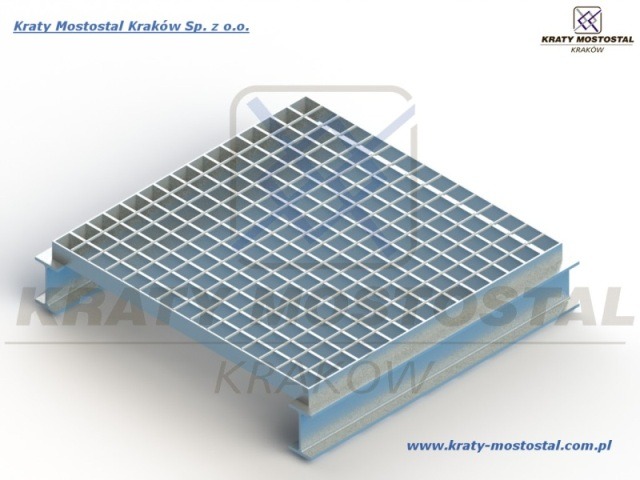

The length of a load bearing bar should coincide with the span between the beams of the supporting structure. This dimension is traditionally marked as "L" and also called the grating length. The second dimension is width "B" which is the length of twisted bars. The frame of welded gratings is made of flat bars with the same thickness and height as the load bearing bar.